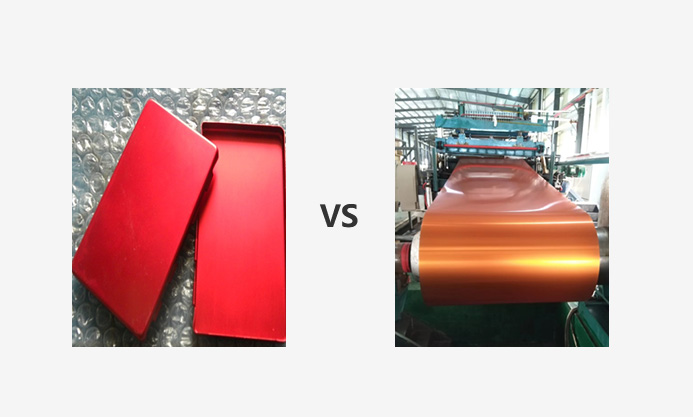

Single oxidation: the oxide film thickness is not uniform, the color difference is large, almost every tank of products out of the color is not the same, and low capacity, not suitable for mass production, especially engineering projects.

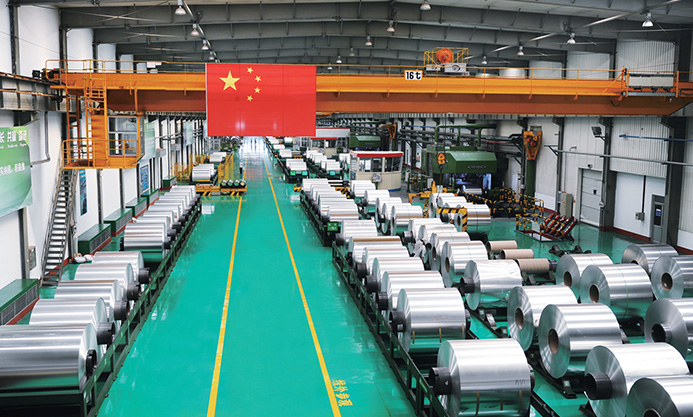

Coil to coil oxidation: uniform oxide film, small color difference, controllable mass production, high capacity.